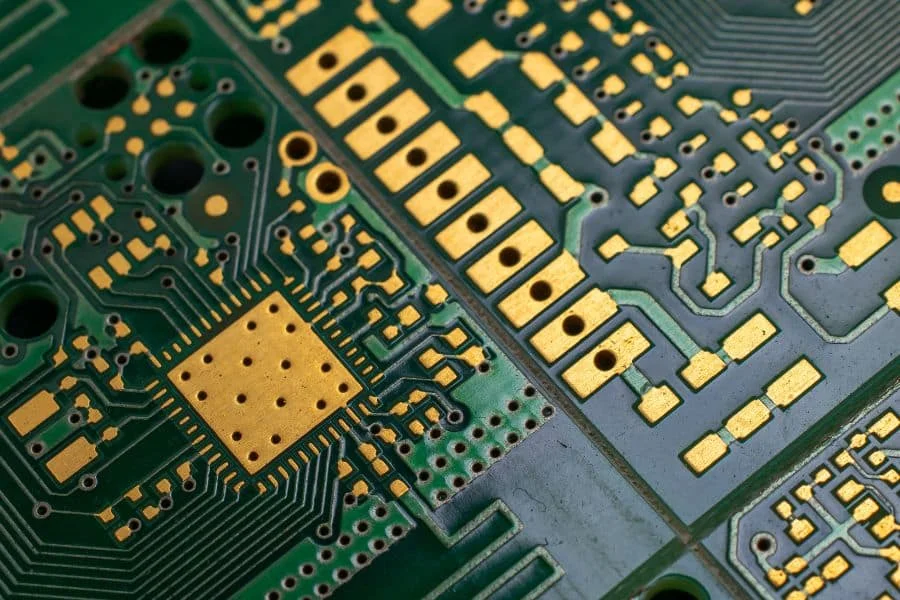

Mercury Electronics Ltd is a premier PCB contract manufacturer at the forefront of design, production, and integration, specializing in security, telecommunications, and industrial control products. With a commitment to innovation and precision, we deliver tailored solutions that meet the evolving demands of these critical industries.

Why Choose Mercury Electronics?

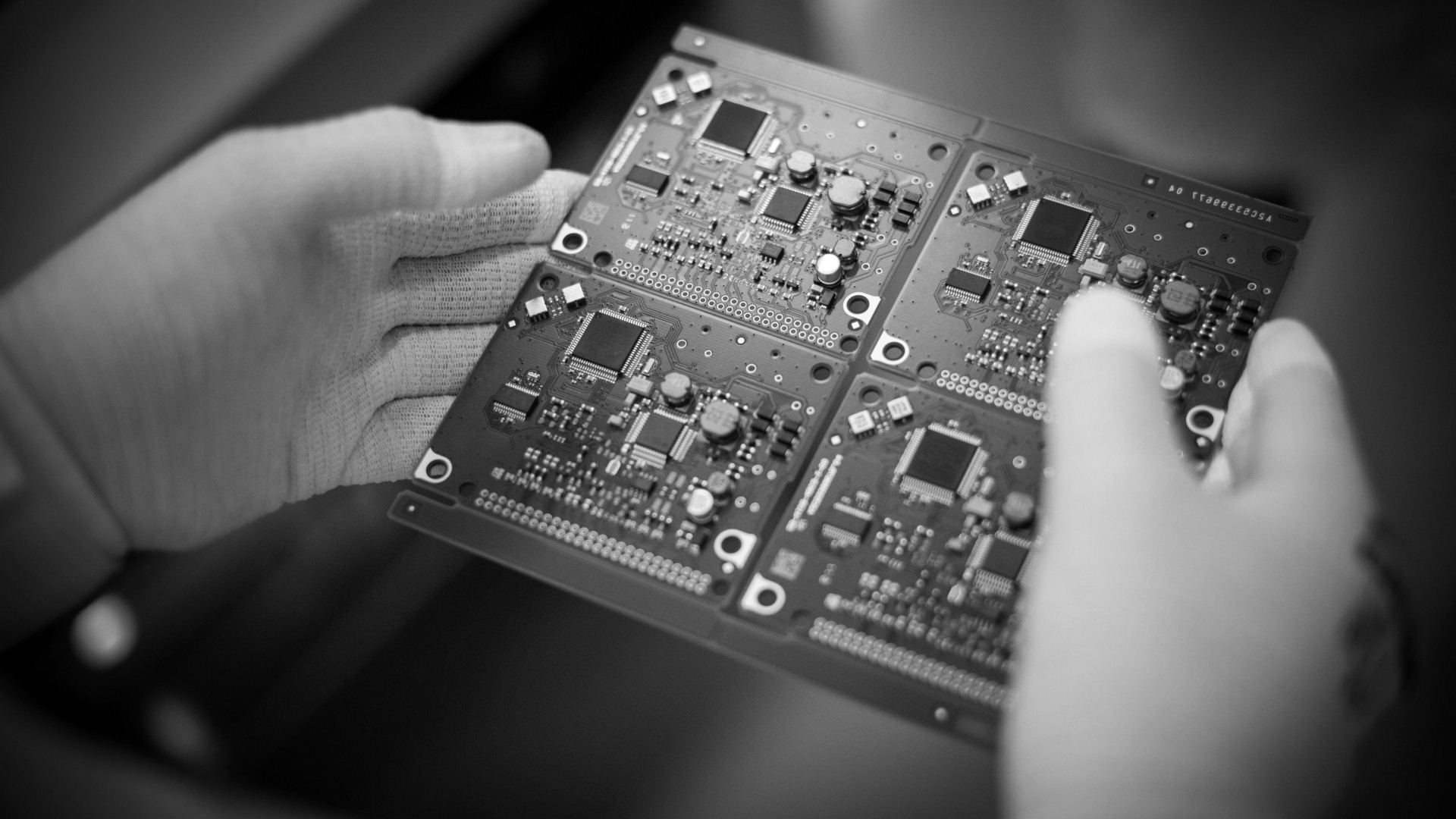

Full Traceability

We ensure complete transparency from sourcing to delivery.

Strict Quality Control

Every unit is tested to meet industry-leading standards.

Rapid Prototyping

Rapid-turnaround prototyping to keep your projects on track.

End-to-End Manufacturing

From design to full box-build, we handle everything.

30+ Years of Experience

A legacy of excellence in precision electronics manufacturing.

Fast & Reliable Delivery

Always on time, with responsive customer communication.

or Contact Us to talk about your requirements

Why Us?

Fast Turnaround

We ensure quick and efficient production to keep your projects moving forward without delays. Our streamlined processes help you stay on track and meet tight deadlines with confidence.

Reliable Support

Our dedicated team supports you throughout your journey — from placing your order to receiving your boards — making sure everything goes smoothly and stress-free.

Innovative Solutions

We specialize in developing creative and forward-thinking PCB designs, continuously evolving to meet the latest demands of the electronics industry.

Our Core Services

Auto-Optical Inspection (AOI)

We ensure unmatched quality and precision through high-speed Automated Optical Inspection at key stages of PCB assembly. Our AOI systems detect soldering defects, component misplacements, and other anomalies to guarantee flawless boards. With real-time feedback and traceability, we minimise rework and maximise reliability.

Ionic Contamination Testing

To ensure long-term reliability and prevent corrosion-related failures, we perform precision ionic contamination testing on all critical assemblies. Using industry-standard methods like ROSE testing, we detect and quantify ionic residues left from soldering and cleaning processes. This helps us meet IPC standards and deliver consistently high-quality electronics

Your Go-To Source for Reliable and Competitive PCB Solutions

Box Build Assembly

We offer complete box build solutions, from PCB integration and cable routing to final system enclosure and testing. Our skilled team handles mechanical assembly, wiring, and functional verification to ensure a fully operational product. With flexible, end-to-end assembly capabilities, we streamline your path from prototype to production.

PCB Prototyping

We deliver fast, accurate PCB prototyping to help accelerate your product development cycle. From single-layer to complex multi-layer designs, our in-house capabilities ensure rapid turnaround without compromising quality. Whether you’re testing a concept or preparing for full-scale production, we provide reliable boards built to your specifications.